| Invention Name | Heavy plow (carruca / wheeled mouldboard plough) |

|---|---|

| Short Definition | Deep-turning plough designed to cut and flip heavy, wet soils |

| Approximate Date / Period | 8th–9th centuries CE Approximate; 820s (term in documents) Certain |

| Geography | Northern & Central Europe (clay-rich regions) |

| Inventor / Source Culture | Anonymous / collective |

| Category | Agriculture; soil preparation |

| Importance |

|

| Need / Reason It Emerged | Wet clay; poor drainage; shallow scratch-plough limits |

| How It Works | Coulter + ploughshare + mouldboard turns the furrow slice |

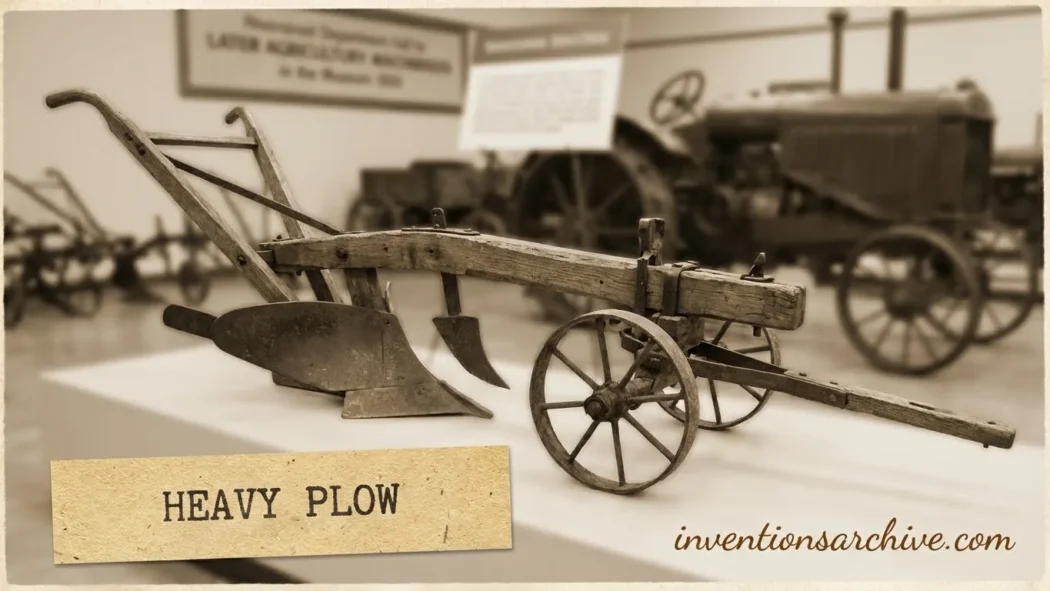

| Materials / Tech Basis | Iron cutting parts; wood frame; wheels; animal traction |

| First Common Use | Large open fields; strip-like plots; shared draft teams |

| Spread Pattern | Gradual regional adoption across Western & Central Europe |

| Developments It Enabled | Ridge-and-furrow; later mouldboard refinements; mechanized ploughing |

| Impact Areas | Farming; land use; rural technology; settlement growth |

| Debates / Different Views | Exact “first” place and date vary by region Debated |

| Precursors + Successors | Ard (scratch plough) → heavy plow → improved mouldboard shapes; steel shares; tractor ploughs |

The heavy plow was built for one stubborn challenge: dense, wet clay. Earlier light ploughs could scratch a line, but they struggled to turn the soil into a clean furrow. A true mouldboard plough changes that moment of contact—cutting, lifting, and rolling the earth so a field becomes workable, season after season. In medieval Latin records it is often linked to the name carruca, a term tied to wheeled, heavy-duty ploughing suited to heavier ground.

Table of Contents

What The Heavy Plow Is

A heavy plow is not “heavy” just because it weighs more. It is heavy because it does more work inside the soil. The design is built to slice, lift, and roll a full furrow slice, especially in sticky ground that resists movement. In many regions the name carruca appears as a label for wheeled, heavy ploughing in medieval documents, showing that people recognized it as a distinct tool—not just a stronger scratch-plough.Details

Core Idea In One Line

The mouldboard is the turning surface: it reshapes a cut slice of earth into a clean furrow, leaving the next pass aligned and predictable.

Early Evidence and Timeline

The heavy plow does not have a single birthday. Its story is a regional timeline: parts appear, designs combine, and adoption spreads where soils demand it. What can be said with confidence is that written records in the early medieval period already treat the carruca as a known implement, and later evidence shows broader use across clay-rich landscapes.

- Early medieval period: Wheeled, heavy ploughing appears in documentary language as a recognized category, not a novelty.

- 8th–9th centuries: Growing signs of wider impact in parts of England and nearby regions; the tool suits heavier soils and can be efficient on larger fields.Details

- Later medieval centuries: Continued refinement of mouldboard shapes, fittings, and draft arrangements as farming systems mature.

How The Heavy Plow Works

The best way to understand a heavy plow is to track one furrow slice. The soil is cut in two directions, then turned. That turning action is the signature. A university-published overview describes the mature heavy-plow package as a combination of three working elements—coulter, ploughshare, and mouldboard—each doing a different cut before the soil flips.Details

What Each Part Does

- Coulter: makes a vertical cut, cleanly opening the slice.

- Ploughshare: makes the horizontal cut under the slice.

- Mouldboard: lifts and rolls the slice, forming the furrow.

What “Turning” Means

Modern agronomy descriptions of moldboard plowing still use the same core verbs: the tool cuts, lifts, and inverts soil with a curved plate, creating a complete turnover of the furrow slice.Details

Major Parts and Materials

The heavy plow is a system: cutting parts, guiding surfaces, and a frame stable enough to hold depth in resistant soil. Many historic versions used iron where abrasion is relentless, and wood where flexibility and repair mattered. Over time, improved metals made the turning surface smoother, helping sticky soils slide instead of clinging.

A Later Material Leap

A museum study of early American steel-plough development notes why polished surfaces mattered so much: as a steel share cut into heavy earth, sticky soil had fewer places to cling on smooth metal, improving the flow of the furrow slice across the mouldboard.Details

Types and Variations

People often say heavy plow as if it is one fixed object. In practice it is a family of designs built around mouldboard turning. Variations reflect local soils, draft animals, and field layouts. The names change, the turning action stays.

Related articles: Horse Collar [Medieval Inventions Series], Wedge [Ancient Inventions Series]

| Variation | Defining Feature | Why It Matters |

|---|---|---|

| Wheeled heavy plough (often “carruca”) | Wheels help stabilize depth and guide the body | More consistent furrows in heavy ground |

| Mouldboard plough (turnplough) | Curved board rolls the furrow slice | True inversion of topsoil |

| Swing plough | No front wheels; guided by the ploughman | More maneuverable, still capable of turning |

| Reversible plough | Turns soil to either side | Reduces ridging; cleaner patterns on slopes |

| Multi-furrow plough | Several bodies in a row | Higher capacity where power is available |

What It Changed in Farming

The heavy plow is best judged by the fields it made practical. Where clay soils once demanded repeated passes, the mouldboard could create a deeper, cleaner furrow in a single run, leaving a more uniform surface. This changed routines: the shape of plots, the direction of ploughing, and the kind of coordination needed when draft power was shared.

Land and Soil Effects

- Better drainage where deep furrows move water away from roots.

- Cleaner seedbed when surface debris is buried by inversion.

- More stable depth with wheeled guidance on uneven ground.

Field Pattern Effects

- Longer runs become efficient when turning is difficult with heavy draft teams.

- Ridge-and-furrow can emerge over time from repeated turning in the same direction.

- Shared coordination increases when draft power and equipment are pooled.

Legacy in Modern Equipment

Modern tillage debates are wide, but one point is steady: the heavy plow left a durable mechanical idea—controlled soil inversion. Today’s mouldboard ploughs, whether pulled by animals or tractors, still rely on the same sequence: a cut, a lift, a turn. Even when farms choose other approaches, the mouldboard principle remains a reference point for what “full turning” means.

FAQ

Is a heavy plow the same as a mouldboard plough?

Heavy plow is a broad historical label for robust turning ploughs built for resistant soils. A mouldboard plough names the turning mechanism itself. Many “heavy ploughs” are mouldboard ploughs, especially when designed for clay soils.

Why were wheels so common on early heavy ploughs?

Wheels can help keep a heavy plow at a steadier depth and improve guidance in uneven, resistant ground. That stability matters when the aim is a consistent furrow.

What problem did the heavy plow solve in medieval Europe?

It made regular cultivation more practical on wet, heavy soils by turning the furrow slice instead of only scratching it. That single change improves drainage patterns and makes fields easier to manage over repeated seasons.

What parts define the classic heavy-plow “package”?

The typical set is coulter, ploughshare, and mouldboard. Together they create a clean slice and then roll it into a stable furrow.

Did the heavy plow immediately transform every region?

No. Adoption followed soil needs, local resources, and established farming routines. In lighter soils, simpler tools could remain practical. In clay-rich areas, the mouldboard advantage became harder to ignore.

What is the safest one-sentence description of its legacy?

The heavy plow made deep, controlled turning a repeatable process, and that turning concept still defines what a mouldboard plough does today.