| Invention Name | Porcelain (early Chinese) |

|---|---|

| Short Definition | High-fired vitrified ceramic; often translucent and non-porous |

| Approximate Date / Period |

Proto-porcelain roots: Shang Dynasty Approximate Mature porcelain traditions: Eastern Han–Tang Approximate Details |

| Geography | China (major kiln regions in North and South) |

| Inventor / Source Culture | Anonymous / collective (kiln communities, artisans, patrons) |

| Category | Materials • Craft • Domestic goods • Trade |

| Importance |

|

| Need / Reason It Emerged | Stronger vessels than earthenware; cleaner surfaces; better glazing control |

| How It Works | Kaolin and/or porcelain stone + glaze; high firing creates a glassy, dense body |

| Material / Technology Basis | Kaolin • porcelain stone • ash/lime glazes • high-temperature kilns |

| Early Use | Tableware • tea • ritual vessels • storage |

| Spread Route | Overland and maritime exchange across Asia; later global demand |

| Derived Developments | Glaze chemistry • kiln engineering • specialized whitewares • later painted porcelains |

| Impact Areas | Art • economy • dining culture • scientific analysis of materials |

| Debates / Different Views | Where stoneware ends and porcelain begins; “first porcelain” dating Debated |

| Precursors + Successors | Precursors: high-fired stonewares, proto-porcelain Successors: refined Song porcelains; large-scale Jingdezhen production |

| Key Dynasties / Kiln Traditions | Han • Tang • Song • Yue • Xing • Ding • Jingdezhen |

| Influential Variations | Celadon • whitewares • qingbai • early underglaze decoration |

Early Chinese porcelain is not just a beautiful ceramic. It is a materials breakthrough that turned common earth into a hard, clean, often light-carrying surface. Its rise depended on the quiet partnership of clay, rock, fire, and patient kiln control.

Table of Contents

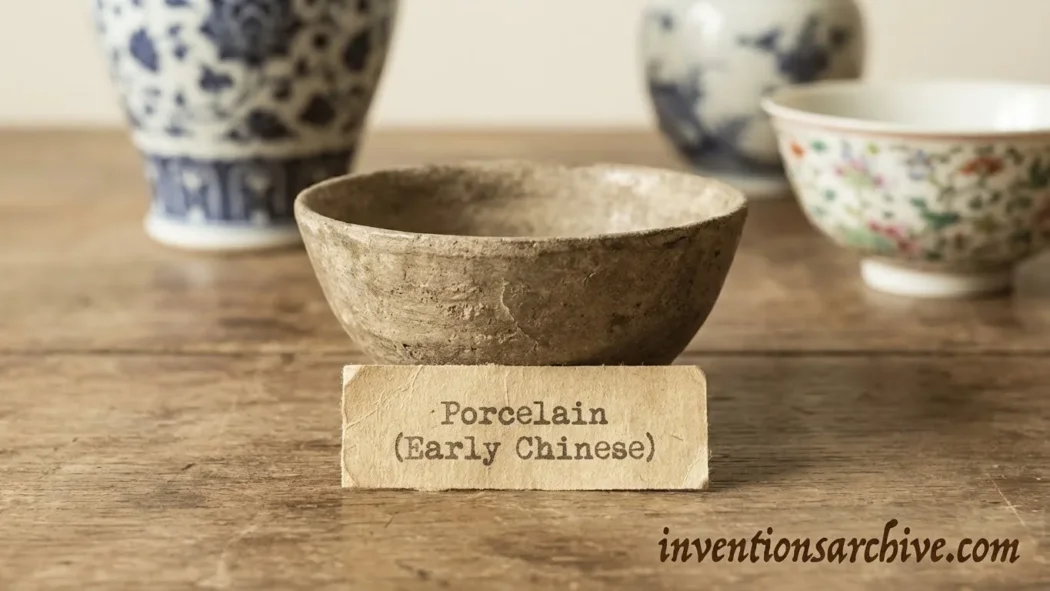

What Porcelain Is

Porcelain is a high-fired ceramic where the body becomes partly glass-like through vitrification. That change is the core. It makes the surface more resistant to liquids, less porous, and often capable of a crisp, bright look.

- Body: fine clay and mineral ingredients that fuse under intense heat

- Glaze: a glassy coating that seals and adds color, texture, or shine

- Sound and light: many porcelains ring clearly and can appear faintly translucent at thin edges

In early China, the boundary between stoneware and porcelain can look like a gentle slope, not a cliff. Some wares feel “porcelain-like” because they are hard and well vitrified, even if they are not pure white. That is why scholars often speak in careful terms such as proto-porcelain or porcelainous stoneware Debated.

Early Evidence and Timeline

The story begins with long experiments in high-temperature firing. Over centuries, kiln practice improved, clays were refined, and glazes became predictable. By the time mature porcelain traditions formed, China already had deep knowledge of heat, airflow, and ash-derived glaze effects.

| Phase | What Changes | Common Look | Dating Note |

|---|---|---|---|

| Proto-Porcelain | Harder bodies; early glaze control improves | Often greenish or olive tones; celadon-like surfaces | Approximate (terminology varies) |

| Early Mature Porcelain | More complete vitrification; cleaner glazes | Whiter bodies appear more often; smoother finishes | Approximate |

| Song-Era Refinement | Specialized kilns; wider styles; consistent quality | Iconic whites and celadons; elegant forms | Well-documented peak of variety |

A helpful way to view the Tang and Song periods is as a shift from “it can be done” to “it can be done reliably.” Museum summaries often highlight Tang growth and Song maturity, including well-known kiln traditions such as Yue in the south and Xing in the north, followed by the Song explosion of regional kiln excellence.Details

Recipes That Made Porcelain Possible

One-Component Bodies

Some early porcelains relied mainly on porcelain stone (feldspathic rock). Fired hot enough, it can form a dense body with a clean surface and a calm glaze response.

Two-Component Bodies

In some centers, recipes mixed kaolin with porcelain stone. That blend can increase plasticity, strength, and control in shaping and firing.Details

How It Works

Porcelain “works” because heat changes the body from a grainy ceramic into a partially glassy solid. When the body reaches a high enough temperature, parts of it melt and flow between particles. After cooling, that fused network helps create hardness, low porosity, and a clean ring when tapped.

The Three Core Elements

- Raw body: clay and rock components that can vitrify under intense firing

- Glaze: a glass-forming layer that seals and colors the surface

- Kiln atmosphere: oxygen-rich or oxygen-limited firing changes glaze color and clarity

One museum overview emphasizes how kaolin near Jingdezhen and extremely high temperatures supported the making of a hard, semi-translucent white ceramic that became a prized trade material.Details

Kilns, Heat, and Glaze

Early Chinese porcelain depends on consistent heat. That usually means long firing cycles, careful stacking, and stable airflow. With reliable heat, glazes melt evenly and settle into a smooth, continuous surface. Even tiny changes in temperature or airflow can shift a glaze from clear to milky, or from jade-green to gray.

Why Early Glazes Matter

- Protection: seals the surface and supports hygiene in daily use

- Optics: clarity, depth, and sheen shape how forms read in light

- Identity: glaze color and texture often signal kiln tradition

Types and Variations

“Early Chinese porcelain” is a family of related solutions, not one single look. Many variations grew from the same logic: refined bodies, hot kilns, and glaze recipes tuned for local materials. The names below are widely used in collections and scholarship.

| Type | Signature Traits | Typical Era Focus | Notes |

|---|---|---|---|

| Celadon (southern traditions) | Green to blue-green glaze; depth like polished stone | Tang–Song | Often linked with careful atmosphere control |

| Whitewares (northern traditions) | Paler bodies; clean, quiet surfaces | Tang–Song | Many forms favor strong silhouettes |

| Ding Ware (a major whiteware family) | Ivory glaze; molded or incised decoration | Song | Large, organized workshops over centuries |

| Qingbai (bluish-white) | Clear glaze with a faint blue cast; thin elegance | Song | Often associated with Jingdezhen’s rise |

| Early Underglaze Decoration | Pigment under glaze; early examples can look restrained | Tang onward | Later became a major visual language |

For a concrete example, a British Museum object record for a Ding porcelain bowl notes long-running workshops in Jianci village, Quyang County, active from the early 8th to the mid-14th century, showing how sustained production supported consistent style and technique.Details

Blue-and-White as a Bridge

Blue-and-white is often discussed because it connects early experimentation to later global fame. A V&A overview notes early appearances in the Tang period and later technical refinement at Jingdezhen, including clay recipe improvements with kaolin in the Yuan era.Details

Uses and Spread

Porcelain’s appeal is practical first. It handles heat well, resists stains better than porous clay, and takes glaze beautifully. That made it ideal for bowls, cups, dishes, and fine storage forms. It also became a language of taste: shape, glaze tone, and surface finish could signal refinement without heavy decoration.

Everyday Roles

- Food and drink: smoother surfaces for repeated use

- Tea culture: forms tuned to aroma, heat, and handling

- Home storage: glazed interiors help protect dry goods

Wider Exchange

- Overland routes: designs and techniques travel with merchants and gifts

- Maritime routes: large volumes of ceramics move through port networks

- Imitation and adaptation: other regions develop local white bodies and glazes

High-quality porcelain could travel far because it packed efficiently and arrived with its surface intact. That combination—beauty plus reliability—helped porcelain become a prestige good in many places, while still remaining useful as daily tableware at home.

How Scholars Identify Early Porcelain

When museums and researchers evaluate early Chinese porcelain, they combine surface reading with scientific tools. The goal is not a single clue, but a pattern that fits known kiln traditions and period practice.

- Body texture: compactness, grain, and break edge character

- Glaze fit: how glaze sits on the body; pooling, thinning, or minute crackle patterns

- Foot and base: trimming marks, firing scars, and kiln support traces

- Form logic: rim profiles, wall thickness, and proportion families

- Lab analysis: mineral composition and microstructure for body and glaze

A Note on Dating

Dating early porcelain can be Approximate because terms and categories shift across regions and modern definitions. Strongest dates usually come from excavated kiln contexts, well-documented collections, and consistent material signatures.

FAQ for Early Chinese Porcelain

Is early Chinese porcelain always white?

No. Many early high-fired wares lean greenish or gray because of clay minerals and glaze choices. “White” becomes more common as bodies and firing control improve, especially in major whiteware traditions.

What makes porcelain less porous than ordinary pottery?

Porcelain is fired hot enough for vitrification. That partially glassy structure closes gaps between particles. A good glaze adds another sealed layer.

What is celadon in the context of early porcelain?

Celadon usually refers to high-fired wares with a green to blue-green glaze. In early Chinese traditions, celadon-like glazes often appear in southern kiln families and can be porcelainous or stoneware depending on body composition and firing.

Why does Jingdezhen appear so often in porcelain history?

Jingdezhen became closely linked with porcelain because of suitable raw materials, deep kiln expertise, and later large-scale organization. Many famous white-bodied wares and later painted porcelains are associated with that region.

How do museums confirm whether a piece is early?

Museums compare form and surface traits with known kiln traditions, then use evidence such as excavation context, historical documentation, and scientific analysis of body and glaze composition.