| Invention Name | Water-Raising Wheel (water-lifting wheel) |

|---|---|

| Short Definition | Rotary device that lifts water using buckets, boxes, or compartments |

| Approx. Date / Era | 1st century BCE (written description) Firm |

| Geography | Mediterranean and West Asia; river and canal landscapes |

| Inventor / Source Culture | Anonymous / collective; documented by classical and later regional records |

| Category | Irrigation • Hydraulic engineering • Water supply |

| Importance | Reliable lift for fields • Steady delivery to channels and troughs |

| Need / Why It Appeared | Higher ground needed water; gravity alone was not enough |

| How It Works | Rotation fills containers; at the top they empty into a trough |

| Power Source Options | Current-driven • Tread-driven • Animal-assisted (via drive mechanism) |

| Core Technology | Wheel + axle • buckets/boxes • sealant • delivery channel |

| First Known Written Description | Vitruvius (Book X, water-raising engines) Details |

| Device Family Terms | Persian wheel (bucket chain) • noria (rim-mounted pots) Details |

| Notable Dimensions (Examples) | Up to ~12 m reported for antiquity • ~20 m example dated to 1000 CE at Hama Details |

| Materials (Common) | Wood (wheel) • stone (supports, aqueducts) • pitch/wax (sealing) |

| Materials Seen in Hama | Poplar wood wheel • stone hydraulic structures Details |

| Early Use Cases | Garden irrigation • saltworks • channel feeding |

| Spread Path | River corridors → canal networks → local craft traditions |

| Derived Developments | Bucket elevators • compartmented lift wheels • pumping design ideas |

| Areas of Impact | Agriculture • urban water handling • craft and maintenance skills |

| Debates / Different Views | Early origins: patchy evidence; terms vary by region |

| Precursors + Successors | Manual lifts → rotary lifts → mechanical pumps |

| Recent Scholarship Example | 2025 reconstruction of Roman tread-operated water-lifting wheels (Water History) Details |

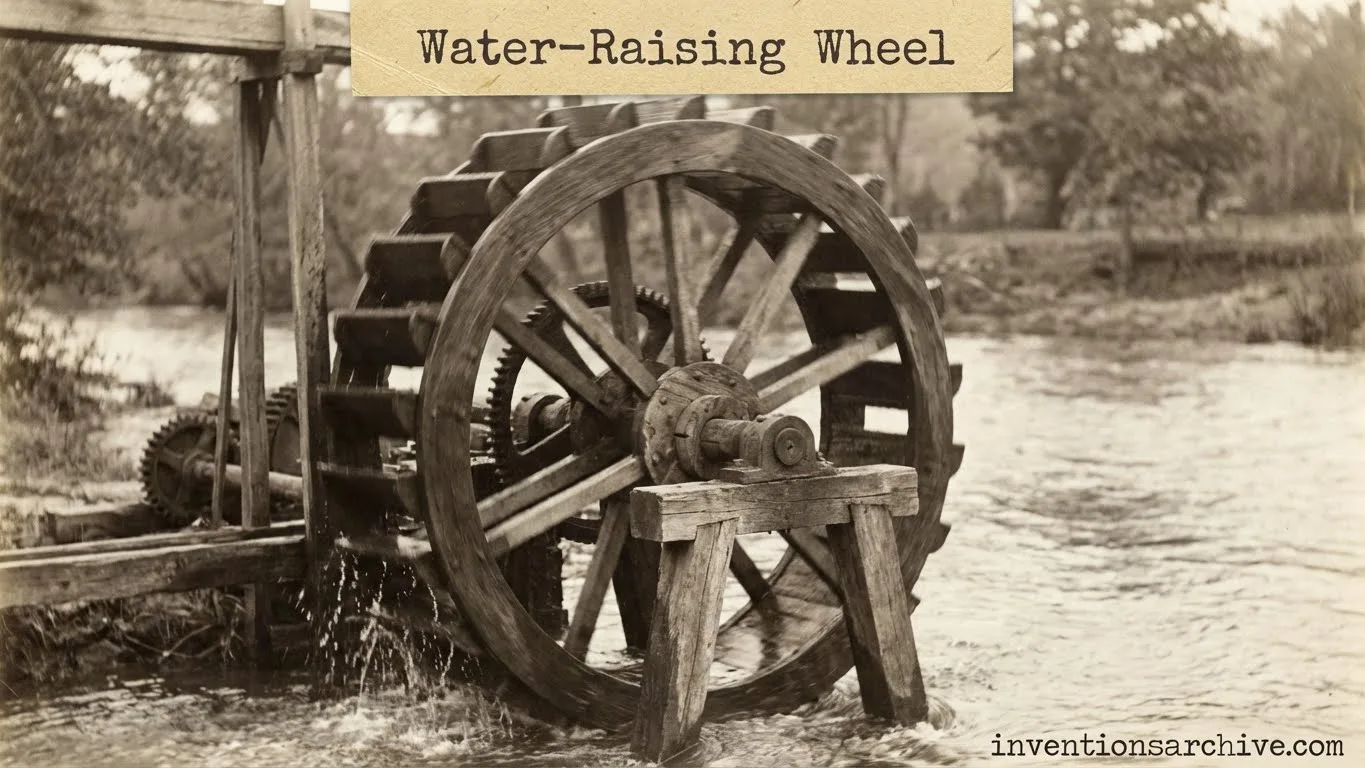

Water-raising wheels are a practical form of water-lifting technology built to move water from a lower level to a higher one with a steady rhythm. They sit at the border between simple craft and serious hydraulic engineering. The idea is direct: a turning wheel carries water upward in buckets or sealed spaces, then drops it into a trough that feeds a channel.

Contents

What the Water-Raising Wheel Is

A water-raising wheel is not just any waterwheel. A mill wheel focuses on power. A water-lifting wheel focuses on delivery. Its job is to move water into a higher channel so gravity can take over again.

The core identity stays the same even when names change. In many texts, the current-driven version is called a noria, while chain-and-pot versions are described as bucket elevators or Persian wheels. The language varies, yet the purpose stays clear: lift water with a turning circle.

What Makes It Distinct

- Continuous motion replaces stop-and-start lifting

- Containers fill low and empty high, with automatic discharge

- Trough + channel turns lifted water into a steady supply

Early Evidence and Timeline

Written evidence places water-raising engines firmly in the classical world. Vitruvius describes several water-lifting machines, moving from low-lift designs to higher-lift systems with boxes and bucket chains. The text reads like a careful inventory, shaped by real use.

- 1st century BCE: written description of multiple water-raising wheels and related devices

- Later centuries: larger, more site-specific wheels appear where rivers, banks, and channels allow big diameters

- Medieval period: very large norias are recorded, including notable examples dated around 1000 CE

- Modern continuity: some historic wheel traditions remain maintained where river hydraulics and local craft skills persist

Scale matters because it unlocks head. A larger water-lifting wheel can place its trough and outlet higher. That single choice can turn a riverside flow into a working irrigation network without changing the basic concept.

How the Water-Raising Wheel Works

The mechanism is simple in outline, yet rich in detail. A rotating rim carries water upward. At the top, gravity empties each bucket or compartment into a collector trough. From there, the flow enters a channel, a basin, or a small aqueduct.

Main Parts

- Wheel + axle (structure and rotation)

- Buckets / boxes (water capture)

- Seals (pitch, wax, tight joints)

- Trough (collection at the top)

- Channel (distribution)

Movement Sources

- River current pushing floatboards or paddles

- Treading by people on a wheel or internal steps

- Animal assistance through a connected drive system

- Hybrid setups where conditions allow more than one input

A Clear Flow Sequence

- Entry: water reaches the lower rim, where containers are ready to fill

- Lift: rotation carries the load upward with repeating cycles

- Discharge: containers tip or drain into a top trough

- Distribution: water moves onward through a channel to fields or storage

Types and Variations

Water-raising wheels form a family. The differences come from power source, the style of water carriers, and the way water is delivered to the outlet trough. Several patterns appear again and again.

Current-Driven Noria

A noria uses river current to turn the wheel. Pots or chambers fixed to the rim fill low and empty high into a trough. It fits sites where flow is steady and a wheel can be anchored safely.

Tread-Driven Tympanum

The tympanum is a low-lift design. It uses internal compartments and small openings to move a large volume quickly, often for irrigation where head is modest but demand is high.

Compartmented Box Wheel

This version carries sealed boxes around the rim. Each box behaves like a portable container. It is conceptually clean: lift, rotate, discharge. With careful sealing, losses stay low and the delivery stays predictable.

Chain-and-Bucket Lift

Here, a chain carries buckets in a loop. As the drive wheel turns, buckets rise, then tip at the top. The method is flexible in wells and confined spaces, especially when a vertical lift is needed without a huge diameter wheel.

Persian Wheel (Bucket Elevator)

The Persian wheel places many small pots on a moving loop. It behaves like a continuous elevator. The effect can feel almost modern: repeatable, steady, and suited to long hours of work when the drive remains consistent.

| Type | Power Input | Water Carrier | Best Fit | Lift Profile |

|---|---|---|---|---|

| Noria | Current | Rim pots | Rivers, stable banks | Medium |

| Tympanum | Treading | Internal compartments | Low head, high volume | Low |

| Box Wheel | Treading / geared | Sealed boxes | Channels, controlled output | Medium |

| Chain Lift | Mechanical drive | Buckets | Wells, narrow shafts | Higher |

| Persian Wheel | Drive wheel | Pot chain | Long runs, steady supply | Medium |

Design Choices That Matter

Performance comes from a few quiet variables. The first is diameter. Bigger wheels raise water higher because the discharge point climbs. The second is container volume. Larger buckets raise more per cycle, yet add weight and stress. Then comes rotation speed, tied to current, tread pace, or gearing.

Sealing is not decorative. It is the difference between transport and leakage. Historical designs use tight joints and coatings such as pitch or wax. Even small leaks multiply across many buckets, so maintenance becomes part of the device’s identity.

What Builders Balanced

- Head vs flow: higher lift often means lower throughput

- Lightness vs durability: wood is workable, yet demands care

- Site fit: bank shape, water depth, and channel height

- Repairability: parts that can be replaced without rebuilding the whole system

Materials and Maintenance

Many historic water-raising wheels rely on wood for the rotating body. Wood keeps the structure light enough to turn, yet strong enough to carry filled containers. In living traditions, regular maintenance keeps performance stable and prevents small issues from spreading across the rim.

Support structures often shift to stone: piers, dams, and short aqueduct runs. This division makes sense. Stone holds alignment. Wood handles motion. Together they form a hydraulic assembly that can last when care remains consistent.

Where It Shaped Daily Life

The wheel’s gift is quiet reliability. It can feed irrigation channels at a steady rate, turning a river into a controllable water source. In some settings it also supports industrial needs such as brine handling, where a constant lift is more valuable than short bursts.

It also changed how people thought about water infrastructure. A water-lifting wheel is a moving part inside a larger system: intake, lift, trough, channel, and distribution. That system view—linking mechanism and landscape—is a lasting engineering habit.

Legacy in Modern Concepts

Modern pumps look different, yet the logic of continuous lifting remains familiar. The wheel teaches three durable lessons: keep motion smooth, keep sealing honest, and keep delivery predictable. Even today, the image of an elevating rim helps explain bucket elevators, rotary lifts, and other devices that move material in cycles.

FAQ

Is a water-raising wheel the same as a water mill?

No. A water mill uses water power to do work like grinding. A water-raising wheel uses rotation to lift water into a trough or channel.

What is the main difference between a noria and a Persian wheel?

A noria commonly carries containers fixed to the rim and is often current-driven. A Persian wheel is a bucket elevator where many pots move on a loop, behaving like a continuous lift.

Why were some wheels built very large?

Height comes from geometry. A larger diameter places the discharge point higher, enabling gravity-fed channels to reach wider land without changing the basic mechanism.

What materials were typical in long-lasting installations?

Many systems combined wood for the moving wheel with stone for stable supports. Tight joints and sealants helped containers hold water during the lift, supporting a steady output.

Where does the lifted water go?

At the top, water drops into a trough or basin, then flows into a channel. From there, gravity distributes it to fields, gardens, or storage points with controlled delivery.