| Invention Name | Treadwheel Crane (Walking-Wheel Crane) |

| Short Definition | Human-powered lifting crane using a walking wheel to wind a hoist line. |

| Approximate Date / Period | Roman evidence: 1st–2nd century CE Evidence-Based; European peak use: 13th–15th centuries Approximate |

| Geography | Mediterranean (Roman world); later Western and Central Europe |

| Inventor / Source Culture | Anonymous / collective craft traditions (builders, shipyards, masons) |

| Category | Construction, Logistics, Material Handling |

| Importance |

|

| Need / Why It Appeared | Vertical building; faster loading for ports and large work sites |

| How It Works | Walking in a large wheel turns an axle; the axle winds rope or chain |

| Material / Tech Basis | Wood framing + iron fittings + pulleys + durable fiber rope |

| Early Use Contexts | Large masonry projects; ship loading; heavy block positioning |

| Spread Route | Craft knowledge across trade centers; workshop-to-worksite transfer |

| Derived Developments | Improved hoists; rotating crane platforms; later geared cranes |

| Impact Areas | Architecture, transport, mining, manufacture |

| Debates / Different Views | “First” dates vary by evidence type (texts vs. images vs. surviving cranes) |

| Predecessors + Successors | Pre: windlass hoists, capstans, block-and-tackle; Post: geared cranes, steam cranes, electric hoists |

| Influenced Variants | Single-wheel cranes; double-wheel harbor cranes; fixed tower cranes; rotating jib cranes |

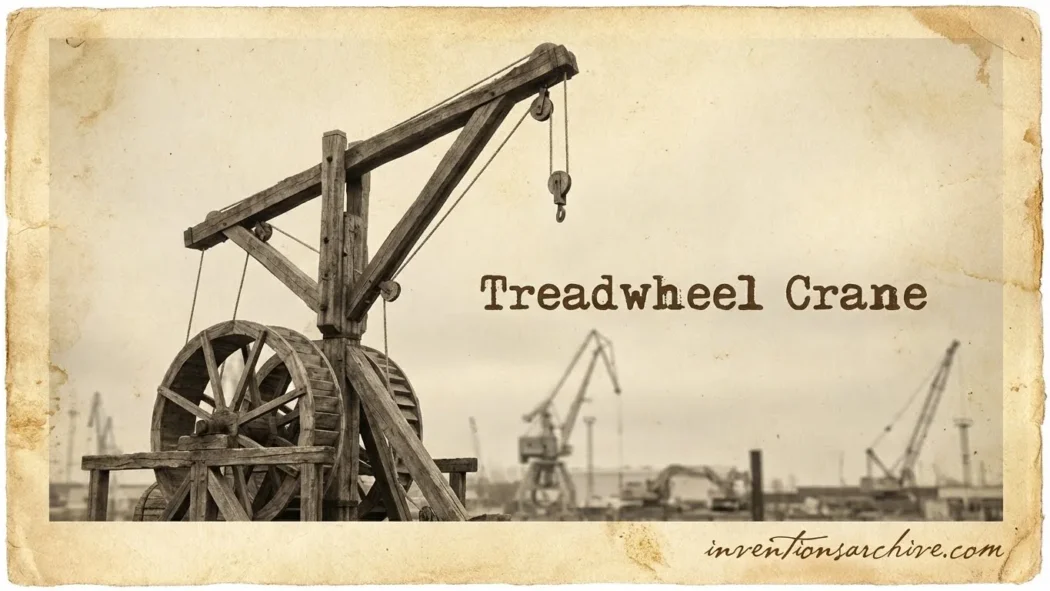

Treadwheel cranes are human-powered lifting machines built for one job: moving heavy loads upward with steady control. A worker walks inside a large wooden wheel—much like walking inside a wide drum—and that motion turns an axle that winds the hoist line. The result is a crane that can raise stone blocks, timbers, and bulky assemblies with a calm, predictable pull.

Table Of Contents

What The Treadwheel Crane Is

A treadwheel crane is a crane whose lifting power comes from walking rather than animals or engines. The wheel’s diameter gives the operator leverage, turning slow steps into a strong rotation at the axle. That axle acts like a drum: it winds the hoist line and raises the load.

Most treadwheel cranes were built as site machines. They were sized for local needs, local timber, and local building habits. Even so, they share a recognizable logic: a large wheel for torque, a stable frame for alignment, and a controlled hoist for safety.

Names You May See

- Treadwheel: the large wheel walked inside

- Walking wheel: plain-language term for the same idea

- Harbor crane: a treadwheel crane used for cargo handling

- Tower crane: a crane mounted in or on a tall structure (often for masonry work)

Where The Idea Came From

The treadwheel crane sits inside a broader family of hoisting machines that combine ropes, pulleys, and rotating drums. In Roman technical writing, these ideas appear as practical systems for lifting and moving loads, including compound pulley arrangements and devices suited to loading and unloading ships.Details

Visual evidence also matters. A famous Roman relief associated with the Haterii includes a depiction of a construction machine powered by a large wheel, directly linking wheel-driven lifting with professional building work.Details

From there, the treadwheel crane becomes a craft solution that different regions adapted. It was not a single, one-time invention. It is better understood as a repeatable principle: turn a large wheel with human steps, convert that rotation into lift, and keep the frame rigid enough that the load stays under control.

How The Mechanism Works

A treadwheel crane works by trading distance for force. Walking around the inside of a large wheel covers more distance than the hoist line moves, so the machine can raise heavy loads with a calm, steady pull.

What Moves

- Wheel rotates as a person walks

- Axle turns with the wheel

- Drum (or axle surface) winds rope or chain

- Hook rises as the line shortens

What Keeps It Controlled

- Frame prevents sideways flex

- Guides keep the line from rubbing

- Braking elements slow or hold the axle

- Signals and teamwork coordinate lift and placement

In many designs, the hoist line runs through pulleys. This can change the direction of pull, reduce swing, or increase mechanical advantage. The wheel provides the main turning power; pulleys shape how that power reaches the load.

Why The Large Wheel Matters

A larger wheel lets the operator apply useful torque with less strain. The motion is smooth, and the rhythm of walking helps maintain a consistent pull. That consistency is a quiet advantage when moving fragile stone or positioning heavy parts near finished surfaces.

Parts You Can Recognize

Although treadwheel cranes varied, the same core parts appear again and again. Learning these pieces makes drawings, museum reconstructions, and surviving cranes far easier to read.

- Treadwheel: the walking wheel (sometimes one, sometimes two)

- Axle: central shaft that carries the wheel’s rotation

- Drum: winding surface for rope or chain

- Hoist Line: rope or chain that lifts the load

- Hook and sling: the connection point for the load

- Mast and jib: the upright support and projecting arm

- Stays and braces: timbers that prevent sway and spread forces

- Sheaves (pulleys): wheels that guide rope and shape lift geometry

- Holding system: devices that reduce backspin and keep the load steady

Types and Variations

“Treadwheel crane” describes a power source, not a single fixed design. Builders combined the wheel with different frames, jibs, and platforms depending on space, load shape, and the need for rotation.

Single-Wheel and Double-Wheel

Single-wheel cranes are simpler and fit tighter structures. Double-wheel cranes can share effort between operators and keep the axle turning with steady momentum. A well-documented surviving example in England is a two-wheel crane associated with the Harwich waterfront heritage record.Details

Fixed Frame and Rotating Platform

Some cranes were essentially fixed: the jib faced one direction and served one lift zone. Others were set on a rotating base so the load could be swung from a hoist point to a landing point without changing the rigging. Rotation did not need to be fast; it needed to be predictable.

Related articles: Crane [Ancient Inventions Series]

Tower-Mounted and Ground-Mounted

A crane could sit on a tall structure to reach upper courses of masonry, or it could stand on the ground for lifting into scaffolds, platforms, or staging areas. The wheel itself might be housed to protect it from weather and to keep the working surface consistent.

| Configuration | Typical Setting | Strength | Trade-Off |

|---|---|---|---|

| Single Wheel | Confined work sites | Compact | Lower steady throughput |

| Double Wheel | Harbors, heavy hauling | Smoother power | Needs more space |

| Fixed Jib | Dedicated lift lane | Simple alignment | Limited swing range |

| Rotating Base | Load transfer areas | Flexible placement | More complex structure |

Worksites And Use Cases

Treadwheel cranes appear where mass meets height. Their story is tied to the everyday needs of large projects: lifting dressed stone, raising beams, setting heavy fittings, and moving cargo safely from quay to storage.

Building Sites

- Masonry blocks and shaped stone

- Timbers for roofs and floors

- Metal fittings and large bells

- Precise placement near finished surfaces

Harbors And Yards

- Loading barrels, crates, and heavy fittings

- Unloading stone, timber, and bulk materials

- Short lifts repeated many times

- Reduced risk of sudden drops through steady control

In technical history, the treadwheel crane is often presented as a key accelerator for lifting work because its principle was known early and it could be applied across many sectors—building, transport, mining, and manufacturing—whenever large loads needed to move upward.Details

Design And Safety Features

A treadwheel crane is most impressive when it looks calm. That calm comes from structure and process working together. The frame spreads forces through braces, while the hoist line stays guided and clear.

- Stiff framing: reduces sway and keeps the wheel aligned

- Clear hoist path: prevents rope rub and uneven winding

- Holding and friction control: helps prevent runaway backspin

- Team coordination: clear signals and paced lifting protect both load and structure

Because the operator’s motion is continuous rather than jerky, the machine naturally encourages controlled lifts. That makes it suitable for heavy items that must be set down gently, not dropped into place.

Materials And Build Quality

Most historical treadwheel cranes were primarily wooden structures, often reinforced where stresses concentrate. Wood was strong, repairable, and workable with local tools. Iron appeared where it made a clear difference: pins, straps, hooks, and high-wear interfaces.

- Wheel: heavy timbers with a durable walking surface

- Axle: stout beam designed to resist bending and twist

- Fastening: wood joints plus iron straps where needed

- Rope: robust fiber chosen for reliability and handling

Even without modern materials, careful craft decisions shaped performance. A wheel that runs true, an axle that stays straight, and a line that winds cleanly will always feel safer and stronger to the people relying on it.

FAQ

Is a treadwheel crane the same as a windlass crane?

A windlass crane is driven by turning handles on a drum. A treadwheel crane is driven by walking inside a wheel, which provides strong leverage and a smooth, steady rotation.

Why were some treadwheel cranes built with two wheels?

Two wheels can share effort and keep rotation more consistent. This helps when repeating lifts or handling heavier loads where steady motion matters more than speed.

What is the oldest evidence for wheel-powered lifting cranes?

One well-known Roman example is a relief associated with the Haterii that depicts a construction machine powered by a large wheel.Details

Did ancient writers describe cranes used for ship loading?

Yes. In Roman technical writing, hoisting machines and pulley systems are discussed as practical tools, including uses connected to loading and unloading ships.Details

Where can a surviving treadwheel crane be seen today?

A notable surviving example in England is documented in the official Historic England record for the Harwich treadwheel crane.Details

Why do historians treat treadwheel cranes as important beyond construction?

Because the same lifting principle supports many sectors. It strengthens the capacity to move heavy loads in building, transport, mining, and manufacturing—wherever vertical handling shapes productivity.Details