| Item | Value |

|---|---|

| Invention Name | Ropewalk Machinery |

| Short Definition | Mechanized systems that spin, strand, and lay fibers into rope along a ropewalk. |

| Approximate Date / Period | Early 19th Century ApproximateDetails |

| Geography | Industrial ports in Europe and North America |

| Inventor / Source Culture | Collective craft tradition; notable mechanization linked to Daniel Treadwell (recorded for a major ropewalk)Details |

| Category | Materials • Manufacturing • Industrial Engineering |

| Need / Driver | Long rope lengths; uniform quality; higher throughput |

| How It Works | Opposite twist stages; traveling carriage; controlled tension |

| Materials / Technology Base | Plant fibers (hemp, manila); later synthetic fibers; gears, shafts, flyers |

| First Major Use Context | Maritime rigging, docks, construction cordage |

| Spread Route | Workshop ropewalks → dockyards → industrial mills |

| Derived Developments | Standardized cordage; continuous production layouts; later wire-rope machines |

| Impact Areas | Trade • Shipping • Building • Industry • Education (craft knowledge) |

| Debates / Different Views | Multiple origins; “single inventor” claims rarely fit the evidence |

| Predecessors + Successors | Hand twisting tools → ropewalk machinery → compact laying machines |

| Key Societies / Institutions | Dockyards; engineering record programs; heritage ropeworks |

| Influenced Variants | Plain-laid • Cable-laid • Shroud-laid • Braided (machine-based) |

| Representative Ropewalk Scale | Quarter-mile class buildings for long runsDetails |

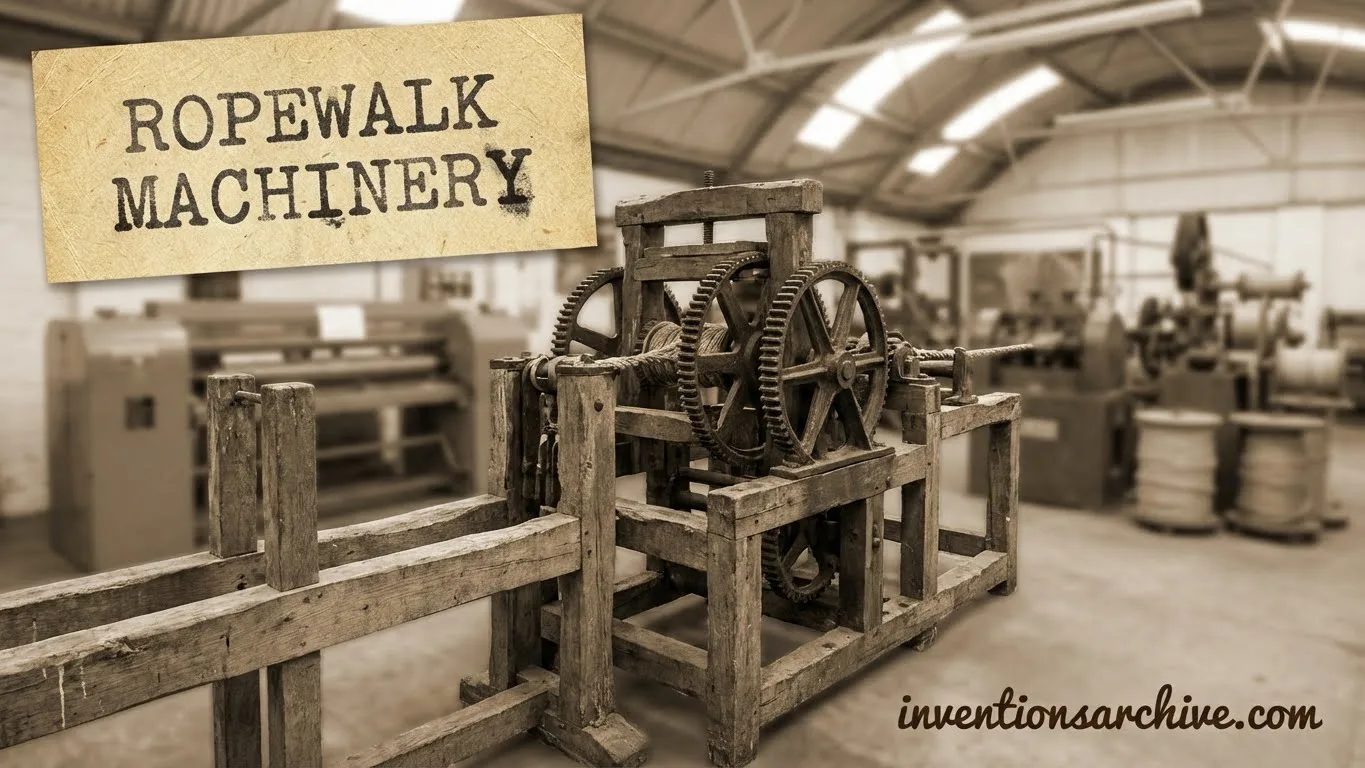

Ropewalk machinery is not one single device. It is a coordinated line of machines that turns loose fiber into finished rope with repeatable twist, steady pull, and consistent thickness. The magic is simple: each stage prepares the next, and the whole line keeps tension under control.

Table Of Contents

A Clear Way To Picture It

Think of ropewalk machinery as a production line stretched into a straight path. Fiber becomes sliver, sliver becomes yarn, yarn becomes strand, and strands become rope. Each step changes structure, not just thickness.

Why The Long Building Matters

A ropewalk is long because length is a tool. It gives room for a moving carriage to keep pull steady while twist builds up. Historic ropewalks reached quarter-mile scale in major sitesDetails, letting machines make long runs with fewer joins.

What Ropewalk Machinery Is

Ropewalk machinery refers to the mechanized tools used inside a ropewalk to shape fibers into rope by controlled twisting. It includes both the machines that create the building blocks (yarns and strands) and the machines that close them into finished rope.

- Spinning equipment turns prepared fiber into yarn.

- Stranding equipment twists multiple yarns into strands with even tension.

- Laying (closing) equipment twists strands into rope, using balanced twist direction for stability.

- Carriages and tracks manage distance, pull, and alignment across the walk.

One detail sits at the center of everything: opposite twist. Stages twist in alternating directions so the rope holds its shape instead of untwisting. This idea appears in modern technical descriptions of rope manufacturing and structureDetails.

Why Ropewalks Got Mechanized

Consistency At Scale

Hand methods can make strong rope, yet uniform output is hard when every step depends on a person’s pace. Mechanization brought repeatable tension, steadier twist, and more predictable diameter. That matters when rope must behave the same way from one coil to the next.

Length Without Splicing

Ropewalks exist for a simple reason: length. The walk limits how long a piece can be made without joining. Technical references note that ropewalk length directly caps production length in the classic setupDetails. Machinery made that long distance easier to manage, especially when a moving carriage did the pulling instead of constant walking.

A Real-World Snapshot

At major historic sites, enclosed ropewalks paired long buildings with machine power and carriage tracks. One well-documented example describes a quarter-mile ropewalk where machines spin fibers into slivers, twist slivers into yarn, and then use a moving cart to twist yarns into strands and strands into ropeDetails. The point is not the location. The point is the system: staged twisting plus controlled travel.

Machines and Parts

Ropewalk machinery looks different from site to site, yet the roles stay familiar. Each role answers one question: how does the line keep twist even, fibers aligned, and pull steady?

| Stage | Typical Machine Element | What It Controls |

|---|---|---|

| Fiber Prep | Combing / carding; sliver forming | Alignment; cleanliness; feed uniformity |

| Spinning | Spinning frames; bobbins | Yarn twist; thickness; delivery speed |

| Stranding | Formers / bunchers; flyers | Strand lay; tension balance |

| Closing | Rope-laying (closing) machine; capstan pull | Final rope twist; take-up; stable structure |

| Travel | Carriage (traveler) on track | Distance control; even pull; strand grouping |

The Rotating End

At one end, hooks or flyers rotate to create twist. Bobbins feed yarn or strands forward. Good layouts keep each line’s path clean, so fibers do not snag and tension stays smooth.

- Hooks: hold multiple ends at once.

- Flyers: rotate the package that forms strand or rope.

- Bobbins: store yarn or strand for controlled feed.

The Moving End

The moving carriage is the quiet hero of ropewalk machinery. It travels down the walk, pulling material at a measured pace while twist builds behind it. In mechanized ropewalk descriptions, the cart on rails is central because it keeps pull steady across a long distanceDetails.

- Carriage wheels: track straight travel.

- Gathering point: where separate ends meet into one strand group.

- Guide or register: keeps spacing consistent so the lay looks even.

Power and Motion

Early mechanized ropewalks used prime movers that could turn multiple stations at once. What matters is not the fuel. It is the transmission: shafts, belts, gears, and clutches that keep rotation stable while the carriage advances. When rotation speed and travel speed drift apart, rope becomes uneven.

A Note On Recorded History

Engineering survey records highlight certain ropewalks as milestones because they tie building design and mechanization together, and they name key figures associated with that mechanized shiftDetails. That kind of documentation helps separate dated claims from verifiable timelines.

How The Twist Stays Even

Rope strength depends on structure, and structure depends on balanced twist. Many technical descriptions stress alternating twist direction across stages for stabilityDetails. Ropewalk machinery makes that balance practical at length.

Opposite Twist Stages

The system alternates direction on purpose. A stage twists components one way; the next stage twists grouped components the other way. The result is torsional stability, meaning the rope resists unwinding when handled.

Tension As A Quality Control

Tension is not a side effect. In ropewalk machinery, it is a control variable. A steady pull keeps twist distributed along the length instead of piling up in one spot. Carriage travel speed, capstan pull, and bobbin drag all shape the final lay.

Why The Ropewalk Layout Works

A long straight run reduces bends and keeps the forming bundle aligned. That alignment makes the finished rope look clean and behave predictably. It also supports the classic ropewalk advantage: making longer pieces before any joining becomes necessary.

Types and Variations

Ropewalk machinery evolved as a family of solutions. Different sites favored different layouts, yet each aimed for the same outcome: stable lay across long lengths with minimal variation.

Open-Air Ropewalks

Earlier ropewalks could be straight outdoor lanes with simple rotating tools. The method relies on distance and coordination, not a building. It is direct, and it makes the core mechanics easy to understand.

- Strength: simple layout, low complexity.

- Limit: weather and surface conditions can affect consistency.

Enclosed Mechanized Ropewalks

Enclosed ropewalks bring the process indoors and integrate power, tracks, and multiple stations. A documented example describes machines handling every phase, from fiber preparation to final rope, with a moving cart doing the long pull along railsDetails.

- Strength: consistent environment and steadier motion.

- Limit: large footprint; significant maintenance needs.

Working Heritage Ropeworks

Some places still demonstrate ropemaking with historic machinery, keeping craft and industrial practice visible to the public. One long-running ropery notes a double ropewalk at quarter-mile length and emphasizes that rope continues to be made there today, with live demonstrations and a working ropemaking machineDetails. That continuity is rare, and it shows how durable the basic ropewalk machinery concept is.

Compact Laying Machines

Industrial production also uses rope-laying machines that compress the ropewalk idea into tighter equipment. Technical references describe rope-laying machines with distinct subassemblies for twisting and pulling, and they note how machine design can limit or extend achievable length depending on take-up designDetails. The goal remains the same: controlled twist plus steady take-up.

Materials and Output

Ropewalk machinery was built around the materials available at the time. Plant fibers shaped early machine choices because they need careful preparation to spin evenly. Modern fibers change the handling, yet the structure—yarn to strand to rope—still follows the same logic.

- Natural fibers: hemp, manila, sisal; valued for grip and traditional handling.

- Synthetic fibers: often stronger for size; different stretch and wear behavior.

- Wire rope: a later branch that uses related ideas, but with metal strands and specialized machinery.

What Makes A Ropewalk Line “Good”

Even Feed

Even feed keeps twist uniform. When bobbins deliver material at different resistance, one component tightens faster and the rope can look lumpy. Good machinery balances drag and keeps paths aligned.

Stable Rotation

Rotation must stay steady under load. If speed surges, twist density changes and the rope’s feel changes too. In descriptions of mechanized ropewalk practice, the combination of powered rotation and controlled carriage travel is a key stabilizerDetails.

Clear Definitions Of Rope Types

Rope types are not just labels. They describe structure: how many strands, how the lay is set, and whether balance is built in. Technical references outline manufacturing phases and the machines used to form and lay strands, giving a shared vocabulary for comparing different ropewalk setupsDetails.

Why Ropewalk Machinery Matters Today

Ropewalk machinery sits at a crossroads of craft and engineering. It shows how a practical need—strong cordage made to a predictable standard—can drive system design: long layouts, coordinated motion, and repeatable twist geometry.

It also survives as an educational lens. When people see the carriage moving and the strands closing, they understand that rope is not a simple line. It is a structured composite built through staged twisting and controlled tension, exactly the kind of engineering idea that stays useful across centuries.

FAQ

Is Ropewalk Machinery A Single Invention?

No. Ropewalk machinery is a system that evolved as different machines took over different stages—spinning, stranding, and laying—while the ropewalk layout kept long runs feasible.

Why Are Ropewalk Buildings So Long?

Length supports the moving carriage and keeps the line straight. The longer the walk, the longer a run can be formed before joining becomes necessary. Historic quarter-mile ropewalks are documented as purpose-built for long production runsDetails.

What Is The Traveler In Rope-Making?

The traveler (carriage) is the moving unit that pulls yarn groups or strands down the ropewalk while twist forms behind it. In ropewalk machinery, this moving pull helps keep tension steady across distance, which supports an even lay.

How Do Twist Directions Affect Rope?

Alternating twist directions across stages helps the rope resist unwinding. Technical descriptions emphasize that alternating twist creates torsional stability, shaping how the rope behaves when loaded or handledDetails.

Are Ropewalk Machines Still Used Today?

Yes. Some sites maintain working heritage ropeworks and demonstrate ropemaking with machinery in operation, showing that the ropewalk approach remains practical and teachableDetails.