| Field | Details |

|---|---|

| Invention Name | Printing Press (Movable-Type Press) |

| Short Definition | Mechanical press that prints inked movable type onto paper |

| Approximate Date / Period | c. 1450–1455 Approx. |

| Geography | Mainz, Holy Roman Empire (present-day Germany) |

| Inventor / Source Culture | Johannes Gutenberg (workshop-based development) |

| Category | Communication; Manufacturing; Knowledge Tools |

| Importance |

|

| Need / Driver | Faster book production; repeatable accuracy; growing demand for texts |

| How It Works | Ink on raised type; pressure transfers ink to paper via platen |

| Materials / Technology Base | Metal type; oil-based ink; paper; screw press mechanics |

| Early Use | Books; reference works; official and commercial printing |

| Spread Route | German cities → wider Europe → global printing industries |

| Derived Developments | Iron hand presses; cylinder presses; rotary presses; offset; digital printing |

| Domains Of Impact | Education; science; commerce; libraries; art; public administration |

| Debates / Different Views | “First” often means first mechanized movable-type press in Europe |

| Precursors + Successors | Woodblock printing → movable type → mechanized press families → modern print systems |

| Key People / Cultures | Song China; Goryeo Korea; 15th-century European workshops |

| Influenced Variations | Letterpress; book illustration; newspaper printing; industrial presses |

Printing press refers to more than a machine; it is a repeatable system for turning text into consistent pages at scale. The breakthrough was not only speed. It was reliability: the same layout could be printed again and again, with fewer surprises and tighter control over quality. That stability reshaped how knowledge was stored, copied, and shared.

Table Of Contents

What It Is

The classic printing press is a pressure machine built for one task: making an even impression. Raised characters—movable type—carry ink. A flat surface presses paper onto that inked type. The page appears in a single, controlled pass. Simple in principle. Powerful in outcomes.

It matters because it treats text as a reusable set of parts. A page is not carved once and discarded. It is assembled, printed, taken apart, and assembled again. That shift turns printing into a repeatable manufacturing process rather than a one-off craft.

- Movable type: individual letters or characters arranged into lines

- Forme: locked frame holding the composed page

- Impression: the press action that transfers ink to paper

Early Evidence and Timeline

The printing press did not appear in a vacuum. It sits on older foundations: paper, inks, and earlier printing methods. Across centuries, different regions refined pieces of the puzzle. The European movable-type press is one landmark in a much longer printing story.

East Asian Foundations

European Mechanization

- Mid-15th century: workshop engineering links metal type, ink, and press mechanics

- Late 1455 (probable): completion of the Gutenberg Bible in Mainz Details

- Following centuries: new press families expand speed, size, and durability

This timeline highlights a careful point: “first” depends on what is being measured. Movable type existed earlier in Asia. The European milestone is the tight coupling of movable metal type with a mechanized press workflow that scaled across many shops.

How It Works

A traditional letterpress setup turns composition into a physical surface. Each letter sits proud of its base. Ink sticks to the raised faces. Then pressure pushes paper into brief contact with the inked type. The press is built to keep that contact even, page after page.

In practice, a press run relies on a sequence of stable steps. Not dramatic. Not mysterious. The value is repeatability and alignment.

- Type is composed into lines and locked into a solid page form

- Ink is applied to the raised surfaces with controlled coverage

- Paper is positioned so the page lands in the right place every time

- The impression is made as the platen delivers uniform pressure

- The sheet is released and the cycle repeats

| Core Element | Function | Why It Matters |

|---|---|---|

| Type | Raised letterforms that carry ink | Reusability across pages |

| Forme | Locks the layout in place | Consistency of text position |

| Ink | Transfers cleanly to paper | Sharp edges; durable print |

| Platen + Screw | Delivers controlled pressure | Even impression across the page |

Materials and Technology Base

The press is often credited to a single inventor, yet the working system depends on multiple technical choices. Each choice solved a practical constraint: speed without blur, pressure without damage, ink without smearing, type that holds shape. The result is a balanced toolkit.

Type and Composition

- Interchangeable letters support fast recomposition

- Standard sizes help spacing and alignment

- Locked forms resist movement under pressure

Ink, Paper, and Impression

- Oil-based ink adheres well to metal type

- Paper quality affects sharpness and durability

- Uniform pressure protects readability across the page

These components form a single system. Change one element—ink viscosity, paper moisture, type height—and the entire page can shift in quality. That is why the printing press is remembered as a manufacturing invention, not just a writing tool.

Types and Variations

“Printing press” can describe a family tree. Early presses are associated with hand-powered letterpress. Later designs introduce stronger frames, new motion paths, and higher throughput. The shared thread remains controlled transfer: ink to surface, with predictable results.

| Press Family | Pressure Motion | Typical Strength | Common Output |

|---|---|---|---|

| Wooden Hand Press | Platen via screw | Craft-level consistency | Books; small runs |

| Iron Hand Press | Platen with stronger frame | More stable pressure | Books; refined typography |

| Cylinder Press | Rolling cylinder over type | Smoother continuous motion | High-volume sheets |

| Rotary Press | Cylinders print continuously | Industrial throughput | Mass circulation print |

| Offset Printing | Plate to blanket to paper | Clean images; efficient runs | Books; packaging; magazines |

| Digital Printing | No physical type or plate | Fast changeovers | Short runs; personalization |

Even when modern methods move away from metal type, many core ideas persist: layout planning, color control, and predictable registration. The original press set expectations for what “professional print” should look like: clear, repeatable, and scalable.

Spread and Adoption

Once the movable-type press proved itself, it spread through workshops rather than through a single centralized channel. Skilled labor mattered: typecasters, compositors, press operators, and bookbinders. Each shop became a small production unit with shared standards and local variations.

Related articles: Movable Type Printing (Bi Sheng) [Medieval Inventions Series], Manuscript Illumination [Medieval Inventions Series]

Spread also depended on supply chains. Printing needs paper, ink ingredients, metal, and tools. As those inputs stabilized, printing became less of an experiment and more of a repeatable trade. That shift encouraged more titles, more formats, and more specialized publishing.

Effects On Society

The most visible effect is volume: more pages, more copies, more readers. The deeper effect is standardization. When many people can consult the same edition, it becomes easier to build shared references in education, law, and technical fields. The press strengthened the idea of a stable text.

Where The Printing Press Changed Daily Life

- Learning: textbooks and reference works become easier to distribute

- Science: consistent editions support careful comparison and citation

- Commerce: catalogs, forms, and manuals improve coordination

- Libraries: collecting and organizing printed material becomes a core mission

- Culture: illustrated books and printed art grow as established forms

It also reshaped time. A text no longer had to travel as a single fragile object. It could travel as many copies. That redundancy makes knowledge more resilient. A library fire, a lost shipment, simple wear—none of these needs to erase a work when identical editions exist elsewhere.

Legacy In Modern Printing

Modern printing is a spectrum, from artisanal letterpress to industrial packaging lines. Yet many contemporary expectations trace back to the early press: clean edges, controlled spacing, and repeatable registration. Even digital workflows borrow the mental model of composition: characters, lines, pages, editions.

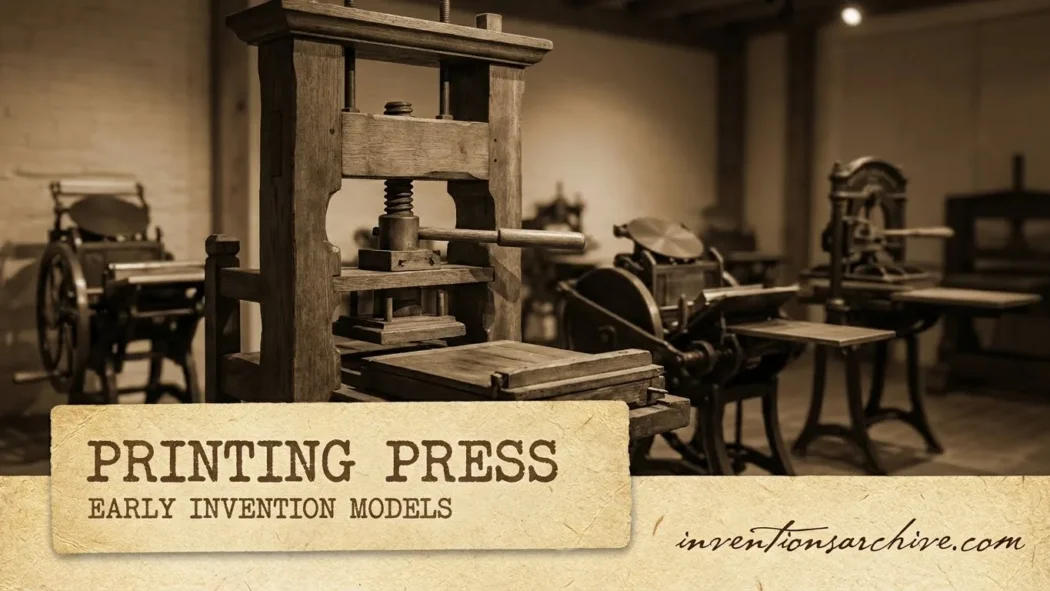

Museums preserve this continuity in tangible form. The Gutenberg Museum’s collection documents printing technology across centuries, including reconstructions of Gutenberg’s wooden press and later iron manual presses, along with machines that expanded typesetting and printing Details. That kind of record helps separate legend from engineering.

Today, the printing press remains a strong symbol because it represents an enduring idea: information can be made portable, stable, and shareable without losing its identity. That is the core legacy—quiet, practical, and still shaping how societies handle knowledge.

FAQ

Who Invented The Printing Press?

Johannes Gutenberg is widely credited with developing the mid-15th-century European movable-type press system, combining metal type, suitable ink, and press mechanics into a scalable workshop process.

What Is Movable Type?

Movable type is a set of separate characters that can be arranged into words and pages, printed, and then reused for new pages. It turns text into reusable components.

How Is A Printing Press Different From Woodblock Printing?

Woodblock printing uses a single carved block for a full page. A movable-type press builds pages from reusable characters, then applies controlled pressure for a consistent impression.

Why Did The Printing Press Reduce The Cost Of Books?

Once type is set, the same layout can be printed many times with predictable results. The cost of composition is spread across more copies, and production becomes more repeatable.

Did Printing Press Technology Stay The Same?

Core principles stayed familiar—ink transfer under controlled pressure—while press designs evolved from wooden hand presses to iron presses, then to cylinder, rotary, offset, and digital systems.