| Invention Name | Medical Scalpel (Detachable-Blade System) |

|---|---|

| Short Definition | Handheld surgical cutting instrument that pairs a rigid handle with a sterile, ultra-sharp blade. |

| Approximate Date / Era | Detachable-blade patent issued 1915 Certain; surgical knives used since prehistory Debated Details |

| Geography | Origin focus: United States; clinical use: global |

| Inventor / Source Culture | Morgan Parker (detachable-blade system); Anonymous (earlier surgical knives) |

| Category | Medicine; surgery; cutting instruments |

| Importance |

|

| Need / Origin Reason | Cleaner edges; faster turnover; more predictable cuts |

| How It Works | Fine bevel concentrates force; blade locks onto a stable handle |

| Material / Technology Basis | Hardened metal blades; precision grinding; detachable fittings |

| First Use Context | Operating theatre; hospital surgery |

| Spread Route | Instrument makers → hospitals → international supply chains |

| Derived Developments | Blade numbering; safety-guard designs; single-use scalpels; microblades |

| Areas of Impact | Surgery; emergency care; dermatology; dentistry; ophthalmology; pathology |

| Debates / Different Views | “First scalpel” (ancient) vs “modern system” (replaceable blades) |

| Precursors + Successors | Precursors: bistoury, lancet, surgical knives; successors: guarded blades, sterile packs |

| Key People / Institutions | Morgan Parker; surgical instrument manufacturers; standards bodies |

| Variations Influenced | Handle families; long handles; micro-handles; guarded scalpels |

A medical scalpel is small, quiet, and exacting. In skilled hands it becomes a tool of precision—a surgical scalpel built to create controlled incisions with minimal drag. Over time, the design shifted from re-sharpened metal knives to the familiar handle-and-blade system, where a fresh sterile scalpel blade can be replaced to keep performance consistent.

Table of Contents

What Medical Scalpels Are

A surgical scalpel is designed for clean, controlled cutting. It is not defined only by sharpness; the defining trait is control. The instrument supports steady movement, predictable edge contact, and a cut that starts exactly where intended. A modern medical scalpel usually separates the durable handle from the disposable blade, so sharpness and sterility stay consistent.

Core Traits

- Fine cutting edge with a narrow bevel

- Stable grip for delicate hand movement

- Sterile blades in modern clinical settings

- Patterned blade shapes for different surgical needs

Common Formats

- Reusable handle + replaceable blades

- Single-use scalpel (one-piece handle and blade)

- Safety scalpel with a guard or retraction feature

- Micro scalpel for fine fields

Why the name matters: “Scalpel” often refers to the modern precision cutting instrument, while older texts may also use terms like bistoury for surgical knives. The function stays similar: a sharp edge guided with care.

Early Evidence and Timeline

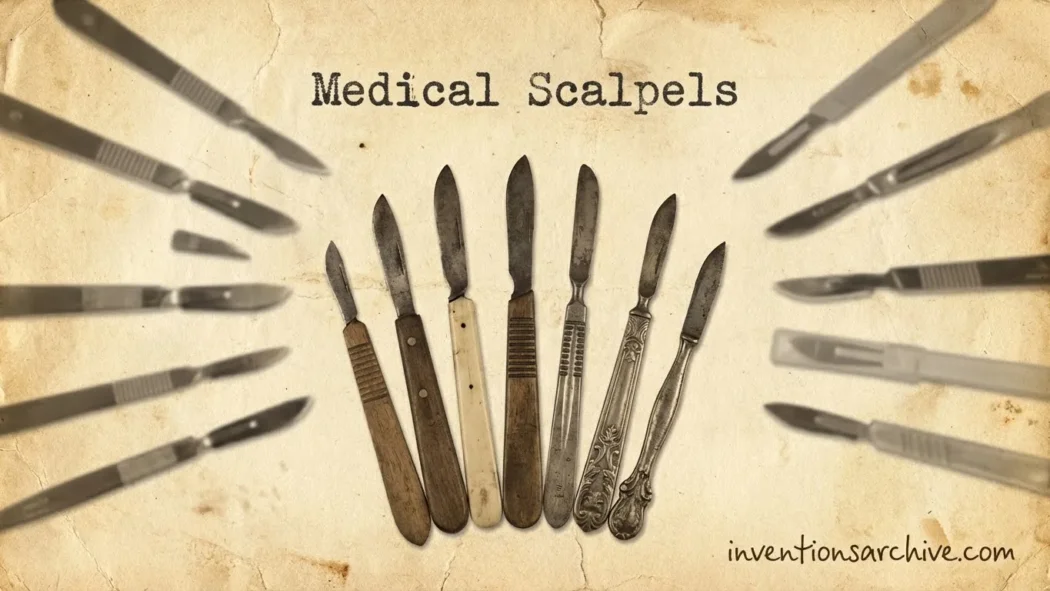

Cutting instruments for medicine are ancient. Early surgical knives existed long before the modern scalpel blade, shaped by the materials available and the needs of care. The real turning point for today’s medical scalpel was the move toward predictable, replaceable blades that supported sterility and consistent sharpness.

- Prehistory to antiquity: surgical knives in many cultures, often re-sharpened and reused

- 19th century: improved metallurgy and precision grinding sharpened reliability

- Early 20th century: detachable blade systems accelerated standardization and safer workflows

- Late 20th century to today: growth of sterile single-use blades and safety-focused designs

Parts and Common Sizes

Most modern medical scalpels follow a simple structure: a rigid handle that provides grip and balance, plus a thin blade that does the cutting. That separation is practical. Handles last; blades change. The result is a familiar tool that can stay consistent across many clinical settings.

Main Parts

- Handle: grip, weight, stability

- Blade: cutting edge, spine, and tip

- Mounting slot: the connection area where blade and handle lock

- Textured surface: helps controlled holding in clinical gloves

Numbering and Patterns

The familiar numbering of many scalpel handles and scalpel blades traces back to early detachable systems: handles were numbered 1–9 and blades 10–20 in the original scheme, and the replaceable-blade approach is tied to a patent issued in 1915 (filed 1914). Details

In day-to-day practice, common blade patterns include curved bellies, fine points, and hook-like shapes. The goal is always the same: a clean incision with predictable control, even when the field is small and the margin for error is tight.

How Medical Scalpels Work

A surgical scalpel works by concentrating force into a very small line: the cutting edge. The thinner the edge and the cleaner the bevel, the less force is needed to start an incision. That matters because control improves when force stays low. A well-made scalpel blade also reduces drag, so the cut feels smooth and predictable.

Why Replaceable Blades Changed Surgery

With a detachable blade, sharpness becomes a managed resource. Instead of repeated sharpening, clinical teams can rely on consistent factory edges. That consistency supports standard procedures and smoother instrument workflows.

Blade Shapes and Variations

Blade shapes are chosen for what they make easy: a long sweep, a tight corner, a precise point, or a controlled hook. The names vary by manufacturer, yet the underlying idea is consistent. A medical scalpel is a family of shapes built around predictable geometry, not a single form.

| Blade Style | Typical Shape | Often Chosen For | Notes |

|---|---|---|---|

| Curved edge | Rounded belly | Long, smooth incisions | Stable contact across a wider arc |

| Fine point | Narrow, sharp tip | Precise starts and small openings | High precision in tight fields |

| Hooked edge | Curved hook | Controlled cutting along an edge | Specialized for guided motion |

| Micro blade | Small, delicate profile | Fine structures and detailed work | Minimal footprint, high control |

Beyond the blade itself, there are also handle variations: longer profiles for reach, slimmer grips for fine work, and angled designs that improve sight lines. These differences look small on a tray, yet they matter because they shape how the surgical scalpel feels in motion.

Related articles: Surgical Instruments (Romans) [Ancient Inventions Series], Tooth Extraction Tools [Ancient Inventions Series]

Materials, Coatings, and Sterility

Modern scalpel blades are typically described as high-grade metal cutting components, often supplied for single use to preserve sharpness and hygiene. In a U.S. device classification definition, a manual single-use blade is described as an interchangeable cutting edge made from a stainless steel alloy, and it may include safety mechanisms such as a protective guard. Details

What “Sterile” Usually Means

- Packaged sterile: blade supplied ready for clinical use

- Single-use: consistent edge and lower contamination risk

- Reusable components: handled through facility sterilization processes

- Traceable lots: supports quality control and recall systems

Why Materials Matter

- Edge retention: how long sharpness stays stable

- Corrosion resistance: important for storage and processing

- Grind consistency: affects how the blade tracks through tissue

- Surface finish: influences drag and feel

Standards and Interchangeability

Interchangeability is one of the quiet strengths of the modern medical scalpel. An international standard, ISO 7740:1985, sets fitting dimensions for two sizes of detachable blade-and-handle features and aims to secure compatibility across countries and manufacturers. The listing notes that it was reviewed and confirmed in 2021. Details

Why this matters: when a handle and blade fit well, the edge stays stable. That stability supports predictable cutting and reduces unwanted movement at the connection point, a small detail with large clinical value.

Safety Design and Clinical Handling

Because a scalpel blade is a sharp and potentially contaminated instrument, modern practice places strong emphasis on risk reduction. In an OSHA interpretation letter, the agency explains that using general instruments like forceps to remove blades does not count as an engineering control because it does not isolate or remove the bloodborne-pathogens hazard from the workplace. Details

Common Safety-Focused Features

- Guarded blades that cover the cutting edge when not active

- Safety scalpels with a built-in retraction or shielding mechanism

- Dedicated blade removal devices designed to contain the sharp

- Hands-free transfer approaches in controlled clinical workflows

Where Medical Scalpels Are Used Today

The medical scalpel appears in many fields because cutting needs differ. A general surgery tray may prioritize common blade shapes, while a micro scalpel supports extremely fine work. The instrument’s core role stays steady: create a controlled incision, with clarity and precision.

- General surgery: broad range of incisions and dissections

- Dermatology: precise surface procedures and biopsies

- Dentistry: controlled soft-tissue work

- Ophthalmology: fine cutting in small anatomical spaces

- Pathology: specimen handling and section preparation

FAQ

What is the difference between a scalpel and a surgical knife?

A scalpel usually implies a precision cutting tool with standardized blade shapes and a consistent edge profile. “Surgical knife” is a wider term that can include older designs and specialized cutting instruments.

Why are many scalpel blades single-use?

Single-use scalpel blades support predictable sharpness and reduce contamination risk. A fresh sterile edge helps maintain consistency across procedures.

What do blade numbers mean?

Numbers are a pattern system used by many manufacturers to indicate blade shapes and compatible handle families. The original numbering approach helped make selection faster in clinical settings.

What is a safety scalpel?

A safety scalpel adds a guard or retraction feature intended to reduce accidental cuts. The goal is safer handling of a sharp instrument within clinical workflows.

Are detachable blades standardized across brands?

Many are designed for interchangeability, and standards such as ISO 7740 define fitting dimensions for detachable blade-and-handle features. Real-world compatibility still depends on exact size families and manufacturer specifications.