| Invention Name | Distillation Apparatus |

|---|---|

| Short Definition | Boil–condense device for separating or purifying liquids |

| Approximate Date / Period | Antiquity–Medieval refinement; 9th–10th century CE Approximate; early origins Debated |

| Geography | Mediterranean; Middle East; later global |

| Inventor / Source Culture | Anonymous / collective; early chemists; major refinements linked to Arabic terminology and practice Details |

| Category | Chemistry; materials; medicine; industry |

| Importance |

|

| Need / Why It Emerged | Cleaner essences; reliable remedies; repeatable laboratory results |

| How It Works | Heat → vapor → cool → condense → collect |

| Material / Technology Basis | Phase change; heat transfer; glass/metal vessels; sealed joints; cooling |

| Early Use Contexts | Perfumery; chemistry; medicine; water purification |

| Spread Route | Workshop practice → scholarly tradition → laboratories → industrial plants |

| Derived Developments | Fractionating column; vacuum operation; packed/tray columns; modern process control |

| Impact Areas | Science; health; fragrances; fuels; environment; education |

| Debates / Different Views | “First” inventor and earliest apparatus form contested |

| Predecessors + Successors | Evaporation → simple stills → reflux columns → specialized short-path units |

| Varieties It Influenced | Alembic; retort; pot still; fractional columns; vacuum and steam setups |

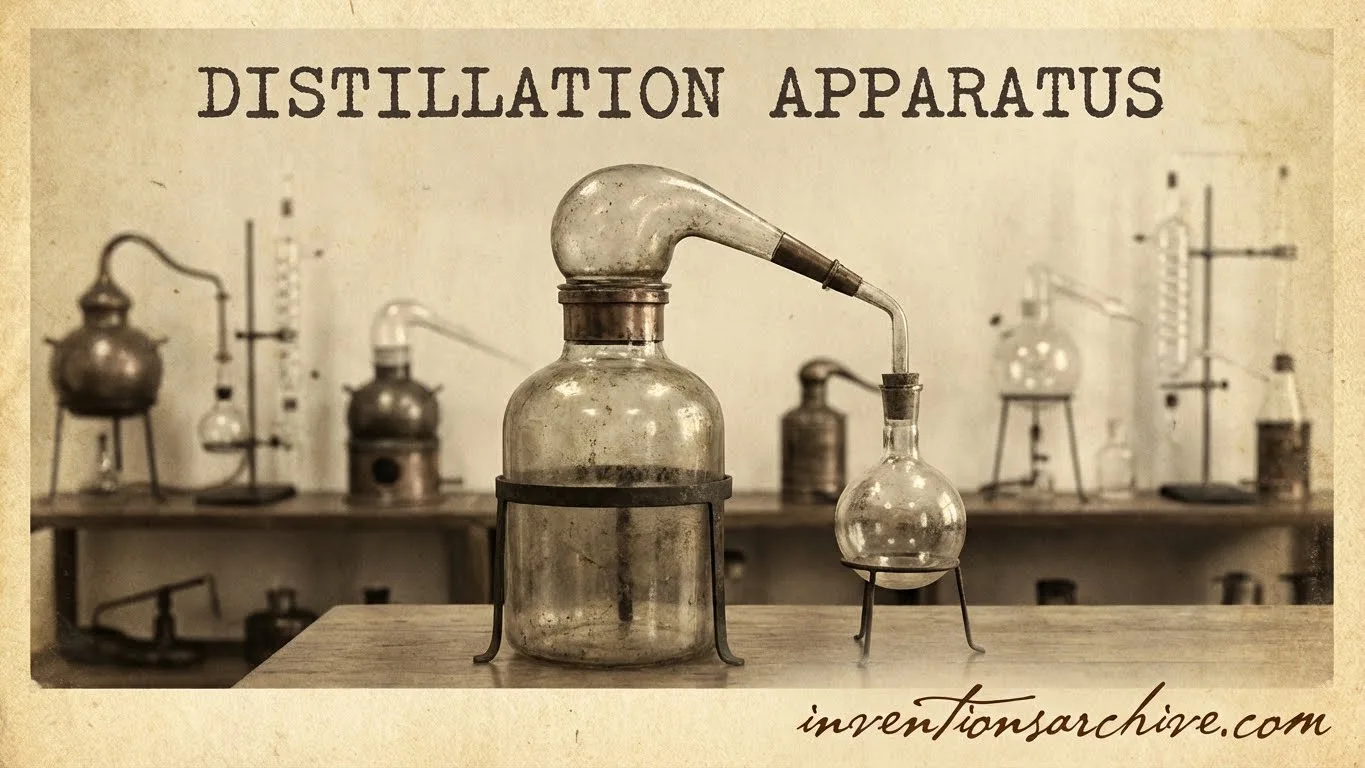

At its core, a distillation apparatus is hardware that makes volatility do useful work. A mixture is warmed until the more volatile part becomes vapor, then that vapor is cooled into liquid again. This simple loop—vaporize, condense, collect—turns messy liquids into cleaner fractions and dependable ingredients Details.

Table of Contents

What Distillation Apparatus Is

A distillation apparatus is not one single shape. It is a family of devices that share one job: move material through evaporation and condensation in a controlled way. The apparatus becomes “simple” or “advanced” depending on what sits between the boiling vessel and the receiver.

In a lab, it might be glassware sized for grams. In a plant, it may be a tower that runs all day. The principle stays the same: a temperature gradient is used to split a mixture into fractions with different compositions.

What Makes It “An Apparatus”

- A sealed path for vapor to travel

- A cooling surface to condense vapor

- A collection point for the new liquid

- Heat control that keeps boiling steady

Key Parts and Materials

Most designs can be read like a map. Start at the boiling vessel, follow the vapor line, pass through a condenser, then end at a receiver. What changes is how the apparatus manages heat and how many “mini-separations” happen along the way.

Core Hardware

- Boiling flask / reboiler (creates vapor)

- Head / column (guides vapor; may add separation)

- Condenser (turns vapor back to liquid)

- Receiver (collects product fraction)

- Thermometry points (tracks key temperatures)

Materials You Often See

Borosilicate glass dominates lab apparatus because it handles heat well and stays chemically quiet. Industrial equipment leans on stainless steels, specialty alloys, and engineered internals. The choice is usually about corrosion resistance, temperature range, and cleanability.

Why glass matters: odorless, transparent, easy to clean, and resistant to many chemicals—features that helped distillation become a dependable scientific tool Details.

How Separation Happens

Distillation depends on a simple idea: components with higher vapor pressure enter the vapor more easily. When the apparatus condenses that vapor, the collected liquid is richer in the more volatile components. The gap in boiling points often predicts how hard the job will be.

One Pass vs Many Passes

Simple distillation is close to “one pass.” Vapor leaves the boiling vessel, condenses once, and you collect it. It shines when one component dominates or when impurities stay behind.

Fractional distillation adds many tiny separations inside a column. Vapor and liquid meet repeatedly, creating a stronger split between fractions. This approach is used when boiling points sit closer together.

Many practical variants are built around the same core hardware, then adjusted for the mixture’s needs—reduced pressure for heat-sensitive materials, added steam for water-insoluble organics, or special solvents for close-boiling liquids Details.

Early History and Evolution

Early distillation hardware is often described through the alembic: a vessel, a domed head, and a receiver. Its shape made collection easier and pushed distillation beyond a crude “open evaporation” practice. Over time, the name stretched from one part to the whole device.

Many historical summaries link key refinements of the alembic apparatus to the 9th–10th centuries CE, while also noting that distillation methods existed earlier in antiquity. That mixed timeline is why the “first inventor” question stays debated Details.

A Quiet Shift That Changed Everything

When distillers began treating the vapor path as a place for control—not just a tube—apparatus design accelerated. Cooling surfaces improved. Joints sealed better. Columns appeared. The device became a platform for repeatable chemistry.

Major Types and Variants

The words “distillation apparatus” can mean a compact lab setup or a tall industrial system. The easiest way to navigate the family is by asking what the apparatus is trying to improve: sharper separation, lower temperatures, gentler handling, or better contact between vapor and liquid.

| Variant | Signature Hardware | Typically Used For | What Makes It Distinct |

|---|---|---|---|

| Simple | Flask + head + condenser | Purifying one main component | Single condensation step |

| Fractional | Fractionating column | Close boiling points | Many internal “mini-separations” |

| Steam | Steam path + separator | Water-insoluble organics | Lowers effective boiling behavior |

| Vacuum | Sealed system + vacuum | Heat-sensitive compounds | Lower boiling temperatures |

| Short-Path | Very short vapor route | High-boiling, delicate mixtures | Minimizes residence time |

| Extractive | Column + added solvent | Close-boiling liquids | Solvent changes relative volatility |

Fractional Distillation Apparatus

In fractional setups, the column is the star. Inside it, rising vapor meets descending liquid. Those repeated contacts amplify separation. Industrial columns mimic the same logic using trays or packing, just at a scale that can fill a building.

Vacuum and Steam Variants

A vacuum distillation apparatus is designed to operate at reduced pressure, which lowers boiling temperatures. This protects materials that degrade when heated too strongly. A steam distillation apparatus is often chosen when target compounds do not mix with water and can co-distill under gentler conditions Details.

Extractive and Azeotropic Approaches

Sometimes boiling points are so close that a basic column struggles. One solution is extractive distillation, where a low-volatility solvent or salt is introduced to shift vapor pressures and widen the separation. In formal terminology, it is defined as fractional distillation carried out in the presence of such a selective, low-volatility additive Details.

Industrial Columns and Internals

Industrial distillation looks different because the apparatus is built for continuous flow. A tall distillation column is usually paired with a reboiler at the bottom and a condenser at the top. Inside, the apparatus creates many controlled contact steps so separation becomes steady rather than occasional.

Trays

Tray columns use staged platforms to bring vapor and liquid into contact again and again. Each stage is a controlled meeting point. This structure helps the apparatus maintain predictable fraction boundaries.

Packing

Packed columns replace trays with structured or random packing. The goal is the same: large surface area for contact. The apparatus can become more compact for the same separation duty.

A Useful Way to Read Any Column Diagram

- Top: cooler zone, lighter fractions tend to rise

- Middle: main separation region

- Bottom: hotter zone, heavier fractions tend to collect

Laboratory-Scale Apparatus in Context

Lab apparatus is built to be modular. A setup can switch from simple to fractional by adding a column, or move to reduced pressure by sealing the system and connecting vacuum equipment. Instructional lab resources often describe these modes and the role of a fractionating column for mixtures that need sharper separation Details.

Typical Lab Signals the Apparatus Is Working Well

- Stable temperature near the vapor path

- Consistent condensation without flooding

- Clean transitions between collected fractions

Why Some Mixtures Stay Hard

- Very close boiling points

- Strong interactions that form constant-boiling behavior

- Heat sensitivity that limits temperature

Where It Is Used

Because it produces consistent liquid fractions, the distillation apparatus became a quiet backbone of modern life. It supports clean inputs for manufacturing, controlled solvents for laboratories, and refined streams for large-scale processes—often without drawing attention to itself.

Chemistry and Materials

- Purifying solvents and reagents

- Recovering valuable fractions from mixtures

- Producing controlled feedstocks

Health and Fragrance

- Isolating aromatic components via steam methods

- Purifying intermediates for consistent formulations

- Supporting quality control with repeatable cuts

Water and Environment

- Producing distilled water for sensitive uses

- Separating components in treatment workflows

- Recovering reusable liquids from process streams

FAQ

What is the difference between a still and a distillation apparatus?

A still is a common name for distillation hardware, often used for simpler setups. A distillation apparatus is broader and includes advanced systems like fractionating columns, vacuum systems, and steam-assisted configurations.

Why does a fractionating column improve separation?

The column creates repeated contact between rising vapor and descending liquid. Those repeated exchanges act like many small separations, producing cleaner fractions than a single pass.

When is vacuum distillation used?

Reduced pressure lowers boiling temperatures. That helps when materials are heat-sensitive or when boiling points are very high under normal pressure.

What does “extractive distillation” mean in practice?

It means the apparatus runs fractional distillation while adding a low-volatility solvent or salt that shifts vapor pressures, making close-boiling components easier to separate in the column.

Is there a single confirmed inventor of the distillation apparatus?

No single, universally confirmed inventor is accepted. Many accounts describe earlier practices in antiquity and later major refinements associated with the alembic tradition, so the “first” claim remains contested.